The Art of AEB-L: Heat Treating and Tempering in Cutlery

Introduction

AEB-L, a low-carbon stainless steel, is favored by knife makers for its excellent edge retention. The processes of heat treating and tempering are essential for transforming this steel into high-quality blades. In this blog, we’ll explore AEB-L and the importance of these processes in crafting superior cutlery.

Understanding AEB-L Steel

AEB-L is renowned for its fine grain structure, which significantly contributes to its performance. With the right balance of carbon, chromium, and other elements, it becomes ideal for kitchen knives and various cutting tools.

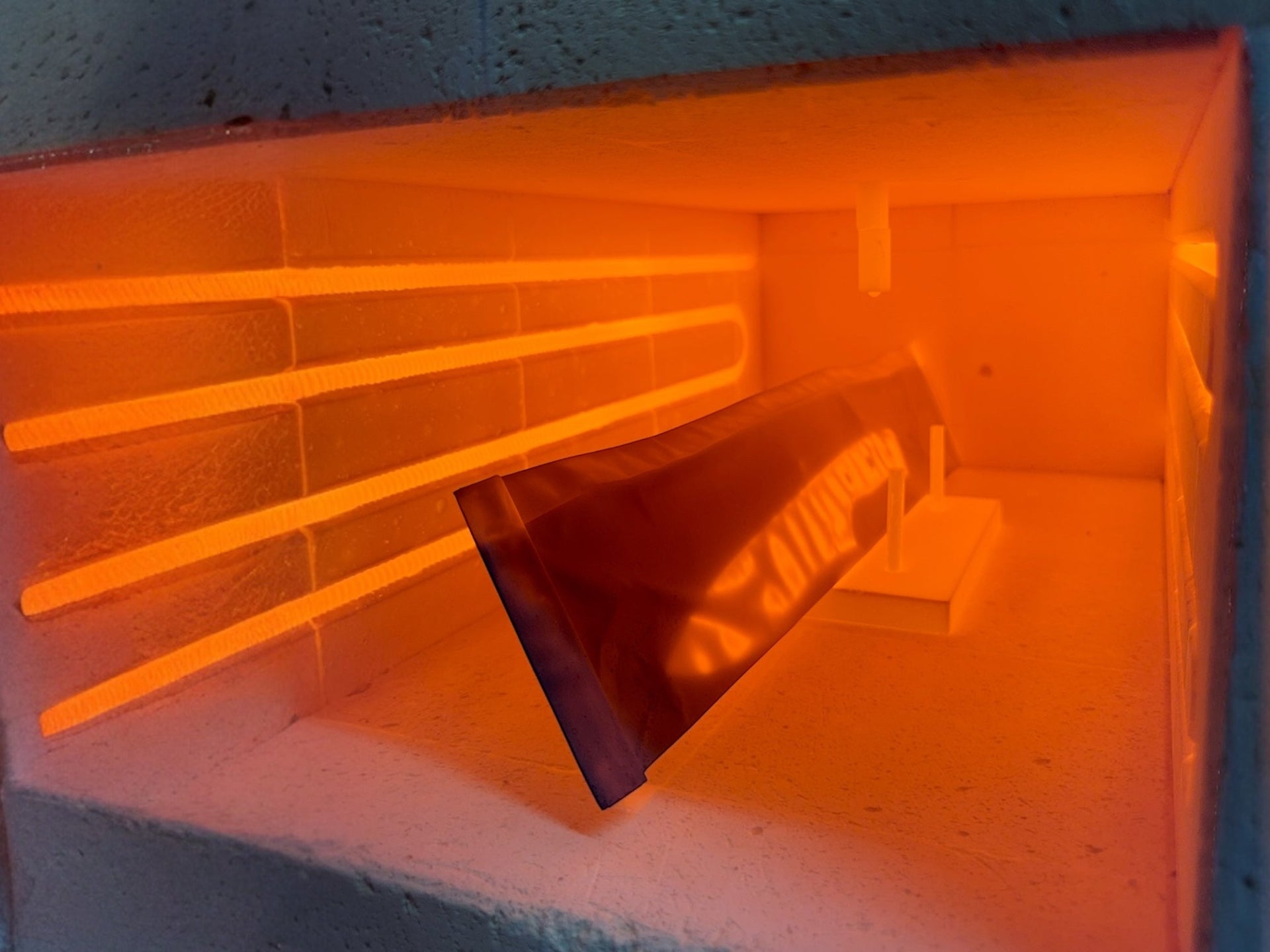

The Heat Treating Process

Heat treating alters the physical properties of AEB-L through a controlled process. First, the steel is heated to around 1900°F (1040°C) to austenitize it, making it malleable. Once at this temperature, the steel is rapidly cooled using air quenching or plate quenching, transforming its structure into hard martensite. While this increases hardness, it also makes the steel brittle, necessitating the subsequent tempering process.

The Tempering Process

Tempering reduces brittleness while preserving hardness. After quenching, AEB-L is reheated to temperatures between 350°F (180°C) and 450°F (230°C) for a set time. This process converts some martensite into tempered martensite, enhancing toughness and ductility. Proper tempering ensures the knife is hard yet resilient, allowing it to maintain its edge and resist chipping.